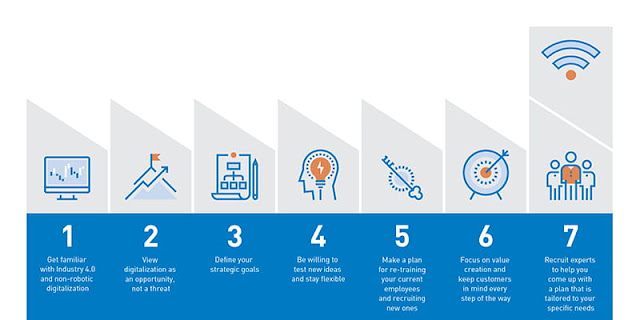

Steps to Take for Digitalization

Change is always a constant, whether it be in your ordinary life or when it comes to your business processes. Previous industrial revolutions dating as far back as the 1700s laid the foundations for change. Each revolution throughout the ages brought about remarkable changes in manufacturing and production. The latest revolution, also known as the Fourth Industrial Revolution or Industry 4.0, brings with it a vast array of technological innovations aimed at making the Smart Factory possible. With innovative technologies like advanced robots, artificial intelligence, cloud computing, the Internet of Things (IoT), and 3D printing emerging to transform the industrial space, it’s no wonder that many companies are preparing for a digitalized future. Digitalization and digital transformation allow manufacturing to harness and integrate the latest innovations and realize impressive gains in productivity and overall growth. However, many companies lack a clear path towards digitalizati...